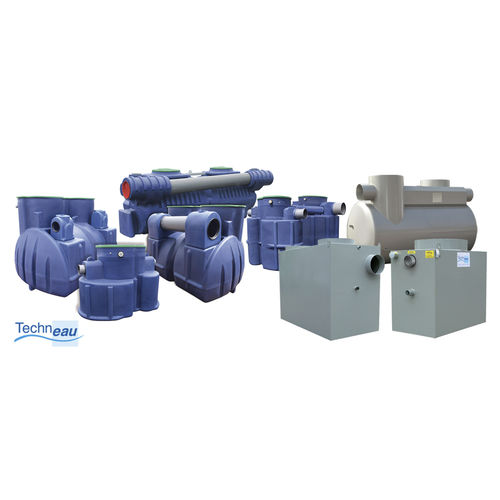

Steel oil separator HYDROPEpolyethylenepolyester

Add to favorites

Compare this product

Characteristics

- Material

- steel, polyethylene, polyester

Description

Introduction

Oil separators allow trapping by density difference, free oil specific gravity of 0.85 (light liquids) present in storm water runoff.

Standards NF and CE

The realization of oil separators shall be subject to the standard NF EN 858.

NF EN 858-1

Principles for the design, performance and testing, marking and quality control.

NF EN 858-2

Installation for separating light liquids.

Operation

The oil separators' operating is based on the density difference between the elements present within the separator.

Light liquids, density 0.85, rise to the surface while heavy materials, density 1, settle to the bottom of the unit.

Useful volumes

The working volume of unit is effective water volume (the amount of water below the outlet pipe level).

Useful volume sludge trap

The minimum working volume of sludge is defined according to the NF EN858-1 :

Vdeb = 100 x TN

Vdeb = Useful in sludge volume l

TN = Nominal size in l/s

Useful volume separator

The useful volume of the separator:

Vsep = 90 x TN

Vsep = Useful volume separator in l

TN = Nominal size in l/s

Recommendations

Beware of undersized separators:

The observation of a correlation between the effective volume of the compartment separator and purification performance highlights, in under 90 seconds dwell time, the phenomenon of re-release of hydrocarbons occurs.

The volume is not important enough to:

Store decanted oil

Provide a flow rate less than 0.09 m / s

Avoid creating preferential currents.

Too much oil separators with sludge are bombs

In case of oil pollution, you could be held liable by the authorities if it is found that the pollution was caused by an undersized oil separator.

Catalogs

Water pre-treatment

56 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.