- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Metal primer FERPLASTpaintedepoxyindoor

Add to favorites

Compare this product

Characteristics

- Support

- for metal, painted

- Component

- epoxy

- Location

- indoor, outdoor

- Other characteristics

- anti-corrosion

Description

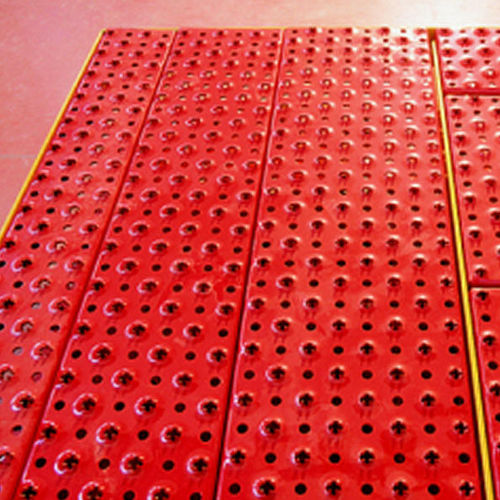

ANTI-CORROSION EPOXY PRIMER WITH HIGH SOLID CONTENT (A+B).

Two component product based on epoxy resins combined with poly amide hardeners.

Due to its high solids content, it allows a huge thickness in one layer only, it is the ideal primer for seeding quartz or iron granulates to make the surface anti-slip.

Quite fast curing over-coating time.

Uses

Anti-corrosion primer for ferrous materials.

Anti-slip primer for metallic surfaces. Preparation of the substrate Ferrous surfaces have to be properly prepared in order to eliminate residues: we advice to do so by degreasing or sand blasting When the surface is already painted, check that the old paint is properly adhered and eliminate eventual presence of corrosion.

Application

Put the two compounds into one container and mix them with a drill mixer.

After the mixing, the chemical reaction between the two compound starts to use the product within the pot-life time.

Apply it by roller or by brush, with a consumption of 0,250 kg/sqm and for a thickness of 200 micron.

When used as primer for anti-slip surfaces, apply around 0,500 kg/sqm, then seeding with iron granulates and/or quartz. When cured, eliminate the exceeding granulates and apply one layer or PAVIPLAST, for a consumption of 0,700 kg/sqm.

Catalogs

No catalogs are available for this product.

See all of SIVIT‘s catalogsRelated Searches

- Coating

- Inside paint

- Wall-mounted paint

- Decorative paint

- Building coating

- Indoor coating

- Exterior paint

- Wall coating

- Acrylic resin-based paint

- Matte finish paint

- Exterior coating

- Decorative coating

- Protective paint

- Interior primer

- Metal paint

- Concrete paint

- Finish paint

- Protective coating

- Concrete coating

- Smooth coating

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.