Lighter and more ergonomic: The new MevaDec generation convinces due to the low weight and ease of cleaning of all its components as well as its optimised handling properties – based on all the tried-and-tested MevaDec system advantages.

Product characteristics

Size and weight

Weight-optimised system for ergonomic and thus efficient work

Largest panel 160/80 cm weighs only 16 kg/m² – almost all requirements can be covered with only on panel size

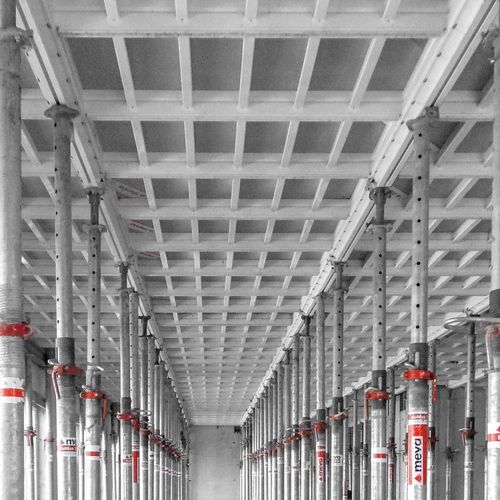

Safety due to prop spacing defined by the system

One system – three slab-forming methods

Drop-head-beam-panel method (FTE)

Primary- and-secondary-beam method (HN)

Panel method (E)

Closed aluminium section

Ergonomic grip profile

High-quality cured powder-coated finish for easy cleaning and reduced concrete adhesion

Sophisticated MEVA product design

High-quality alkus all-plastic facing AL 10 with 7-year long-term warranty

Durable and easy to repair

Compatible with previous generation

Simple handling with panel installation from above and below.

The efficient and ergonomic slab formwork

MevaDec is not bound to a rigid grid pattern, meaning that it can be flexibly adapted to suit any building layout and any slab thickness. Minimized filler areas allow it to be set up more quickly. In the process, the predefined prop spacing ensures safety and optimised material stock on the construction site.

Light, robust panels with ergonomic grip profiles for easy handling.

Fewer compensations saves time. Even uneven slab edges can be solved with a minimum of filler areas.

Fewer job-built solutions save money. Trouble-free connections to conventionally formed areas.