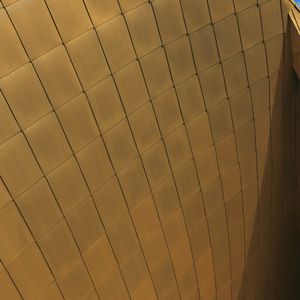

Copper sheet metal TECU® PATINApatinafor facade claddingroof

Add to favorites

Compare this product

Characteristics

- Material

- copper

- Finish

- patina

- Applications

- for facade cladding, roof

Description

In a specially-developed industrial process, TECU® copper sheets are patinated green on one side. This process causes a patina layer to grow on top of a pre-oxidised copper surface – a process similar to the natural patination that occurs over a long period of time when copper is exposed to atmospheric conditions. TECU® Patina is always extremely varied, just as you would expect from a natural surface. The many different colour tones and shades eventually blend together, but only gradually. The unique developments occurring in TECU® Patina are exciting – just as modern architecture should be.

TECU® Patina sheet is manufactured in state-of-the-art production facilities to EN 1172 and KME's own strict guidelines. It is made from Cu-DHP – oxygen-free, phosphorus-deoxidised copper with limited residual phosphorus. Cu-DHP is well suited to welding and soldering, and is minimum 99.9% pure copper. Cu-DHP is outstandingly malleable, regardless of temperature or rolling direction.

TECU® Patina surpasses the requirements of EN 1172 regarding tolerances and the most important material properties. This gives cladding areas their excellent visual appearance.

TECU® Patina is now delivered with TSP surface protection. This temporary yet robust transparent layer ensures long-lasting protection. Processing is virtually dust-free. Fabricating / processing marks on the material's surface are minimised and, even after folding and bending, the patina layer remains in good condition. After installation, the surface develops in the completely natural manner characteristic to copper.

Catalogs

No catalogs are available for this product.

See all of MAZZONETTO‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.