Copper sheet metal TECU® OXIDpatinafor facade claddingroof

Add to favorites

Compare this product

Characteristics

- Material

- copper

- Finish

- patina

- Applications

- for facade cladding, roof

Description

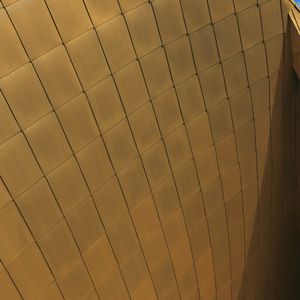

Right from the start, TECU® Oxid has a dark oxidised surface, to bypass the bright initial appearance of new copper and thereby offer a more consistent dark brown colour across different façade elements sooner than TECU® Classic. It resembles the oxidised matt brown surface that gradually develops on copper via natural weathering and oxidation. The copper coils are pre-oxidised at the factory on both sides in a special industrial process.

The brown oxide surface continues to develop after installation; it becomes matt and transforms through dark brown colours, yielding the rich dark brown hues of oxidised copper to the facade. On inclined cladding areas, a patina green, typical for copper, develops through the influences of airborne substances and moisture.

This lively protective layer lends TECU® Oxid its unmistakable appeal and extraordinary durability.

TECU® Oxid coil is manufactured in state-of-the-art production facilities to EN 1172 and KME's own strict guidelines. It is made from Cu-DHP – oxygen-free, phosphorus-deoxidised copper with limited residual phosphorus. Cu-DHP is well suited to welding and soldering, and is minimum 99.9% pure copper. Cu-DHP is outstandingly malleable, regardless of temperature or rolling direction. TECU® Oxid surpasses the requirements of EN 1172 regarding tolerances and the most important material properties. This gives cladding areas their excellent visual appearance.

The special manufacturing technology used for TECU® Oxid creates lighter and darker shades of brown, but these colour variations later disappear as the natural oxidation process progresses.

Catalogs

No catalogs are available for this product.

See all of MAZZONETTO‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.