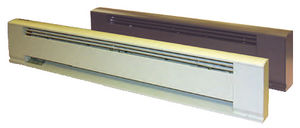

Electric air heater 3470 ceiling-mounted

Add to favorites

Compare this product

Characteristics

- Energy source

- electric

- Installation

- ceiling-mounted

Description

Contractor shall supply and install heavy duty ceiling mounted forced air

electric heater(s) of the wattage, voltage and phase as indicated on the plans. The heater shall so be designed to provide an even distribution of heated air to the space to be heated by drawing return air in the periphery of the heater, across and through the element and be discharged from the center section of the heater by mean of an electric motor and axial flow fan blade.

Motor: Motor shall be permanent lubricated, unit bearing, totally enclosed

shaded pole type with impedance protection. Motors shall operate at no more than 1300 RPM and shall be same voltage as the heater.

Performance: Heaters shall have a rating of 425 CFM at 710 F.P.M. with a

maximum temperature rise of 44°F and 63.9 DB RE 1012 Watt.

Element: Element assemblies shall consist of two or three corrosion resistant steel sheathed type elements mechanically bonded to common corrosion resistant steel fins. Each sheathed element shall consist of helically coiled Nickel Chromium alloy resistant wire completely embedded in and surrounded by Magnesium Oxide,

enclosed and wedged into corrosion resistant steel sheaths. Elements shall have 2

cold conductor pins extending into sheath and shall have a density of no more than 60

watts per inch.

Thermal Overload: Heaters shall be equipped with a manual reset thermal

overload which disconnects elements and motor in the event normal operating temperatures are exceeded. For safety, if opened due to abnormal temperature, thermal overload shall remain open until manually reset.

Catalogs

2021 Heating & Controls

139 Pages

Related Searches

- Infrared heater

- Electric infrared heater

- Commercial infrared heater

- Air heater

- Fan coil

- Convector

- Metal convector

- Horizontal convector

- Wall-mounted air heater

- Electric convector

- Rectangular convector

- Electric air heater

- Wall-mounted convector

- Radiant panel

- Ceiling-mounted radiant panel

- White radiant panel

- Hanging infrared heater

- Linear convector

- Recessed fan coil

- Hot water air heater

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.