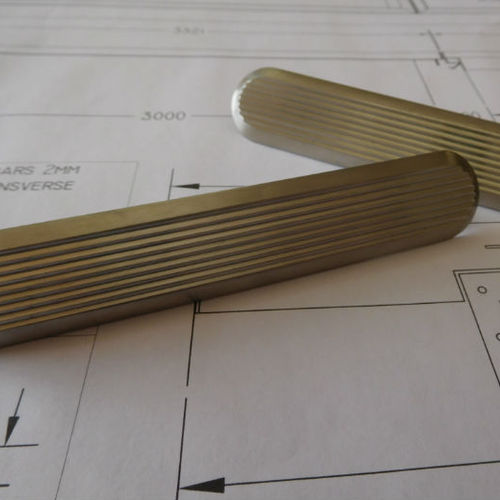

Kent Ridge Tactile Warning Strips Grade 316L Stainless Steel; Satin Finish 320 Grit Polished, the standard dimensions 15.74″ (400mm) long x 0.98″ (25mm) width x 0.19″ (5mm) dept . The Kent Ridge Tactile Warning Strips provide an underfoot warning to identify hazards and dangerous areas where is a change in levels or where there is an unprotected opening such as open stairwells and platforms. The stainless steel material is ideal for high-traffic pedestrian areas and suitable for indoors.

Customizable: Length down to 10.23″ (260mm).

Underfoot warning to identify hazards and dangerous areas

Grade 316L Stainless Steel

Easy installation

Can be incorporated onto the full range of Kent Stainless seats and benches

Slip resistant design

Stainless Steel Maintenance

Clean the stainless steel components using warm water with a mild detergent with a non

abrasive cloth or sponge. Heavier stains may require the use of a nylon scouring pad or a stainless steel cleaner. To remove paint or graffiti (or light concrete splashes) use a cloth and alkaline or solvent paint strippers according to type of paint. For Satin Finish Stainless try to follow the direction of the grain when cleaning vigorously or polishing. For Bead Blasted Finish use a circular motion. Rust spots or 'tea stains' can occur on the surface of the material, these are normally caused by contamination from ordinary mild steel, particularly in areas where construction work has been undertaken. Where contamination of the stainless has occurred from ordinary mild steel coming into contact with the stainless, use Rust Remover 410.