- Flooring & Wallcovering

- Wallpaper, Decorative panel

- Acoustic wall panel

- Jocavi - Acoustic Panels, Lda

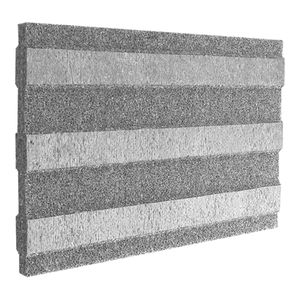

Wall-mounted acoustic panel SEAFOAM®for ceilingmelaminesquare

Add to favorites

Compare this product

Characteristics

- Installation

- wall-mounted, for ceiling

- Material

- melamine

- Shape

- square

- Finish

- fabric look

- Color

- multi-color, colored

- Room/use

- for office, for restaurant, for bar

- Market

- commercial, industrial

- Technical characteristics

- high-performance

- Fire resistance

- Euroclass B-s1-d0, fireproof, fire-retardant

- Ecological characteristics

- 100% recyclable

- Other characteristics

- decorative, design, custom

- Thickness

4 cm, 8 cm

(1.575 in, 3.15 in)- Width

60 cm

(24 in)- Length

60 cm

(24 in)

Description

The SEAFOAM is made of a flexible open-cell foam from melamine resin, a thermoset polymer. This foam is characterised by its three-dimensional network structure which consists of easily shaped thin filaments. The sound waves penetrate the open-cell structure, thus reducing the reflected energy and giving this product an excellent sound absorption capacity.

Due to its low weight, the SEAFOAM allows the creation of large-surface elements that seem to be free-floating, giving rooms an attractive appearance. The simple installation method does not require any additional structural or engineering calculations. Working areas which are exposed to high levels of noise, such as industrial areas, pavilions, among others, can be acoustically restored at a low cost, by reequipping them with these lightweight absorbers. We can make specific shapes and sizes for large projects upon demand. The SEAFOAM’s acoustic and safety characteristics make this product ideal for use as a noise control and sound insulation device in buildings that have demanding requirements against fire. It improves acoustics and soundproofing, thereby providing safety in accordance with environmental standards.

NRC Average: 0,80 /m2

Raw material: melamine resin or standard acoustic foam

Flame resistance: Germany B1, France M1, GB class1, USA V0/HF1

ACOUSTIC FOAM - Self-extinguishable M1 fire-retardant foam

Good thermal insulation properties and humidity tolerance

Constant physical properties over a wide temperature range

Resistance to all organic solvents

Easy installation

Mounting: with glue (sold separately)

Other Jocavi - Acoustic Panels, Lda products

ATP / Absorbent Panels

Related Searches

- Acoustic panel

- Commercial acoustic panel

- Wall-mounted acoustic panel

- Decorative acoustic panel

- Rectangular acoustic panel

- Office acoustic panel

- Ceiling acoustic panel

- Interior acoustic panel

- Colored acoustic panel

- Home acoustic panel

- Public building acoustic panel

- High-performance acoustic panel

- Design acoustic panel

- Wooden acoustic panel

- Fire-retardant acoustic panel

- Textile acoustic panel

- Auditorium acoustic panel

- Sustainable acoustic panel

- White acoustic panel

- Retail acoustic panel

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.