- Kitchen & Bathroom

- Bathrooms

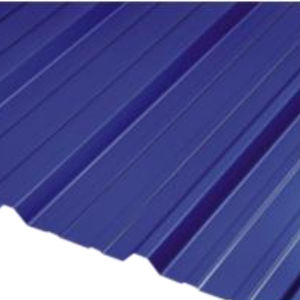

- Furniture panel

- FANGXING BUILDING MATERIALS

Wall-mounted panel FFGI COILSbathroomfor furniturefor building

Add to favorites

Compare this product

Characteristics

- Applications

- wall-mounted, bathroom, for furniture, for building

- Function

- cover, construction

- Technical characteristics

- anti-corrosion, lightweight, insulating, sustainable

- Material

- metal

- Finish

- high-gloss, smooth

- Appearance

- metallic look

- Market

- commercial, home

- Thickness

0.5 mm, 0.6 mm, 0.7 mm, 0.8 mm

(0.02 in, 0.024 in, 0.028 in, 0.031 in)- Width

1,000 mm, 1,200 mm

(39 in, 47 in)

Description

FFGI is lightweight anti-corrosion building material jointly developed by FangXing and Dupont. It is metal panel that laminated with PVDF or PVC Polymer film on both side via melting and pressing process at a high temperature.

FFGI isolate the metal panel from the corrosive materials that gives outstanding characteristic .

This is the main advantage of FFGI Steel compared with PPGI/PPGL steel. FFGI Steel is laminated with Resin Films on both sides, No pre-painting process, No micropores, so corrosive components can not corroded the substrate. So it is stable when FFGI exposed to chemical agents such as industrial emissions, fog, salt, acids, alkali etc.

FFGI Steel can meet Class A requirement of all kinds of buildings, Tested by Fire Research Institute Testing Center.

The Top FILM PVDF material has characteristics of UV resistance, The color for PVDF film can adapt to all normal climate like sunshine, wind, rain and snow, Color last more than 50 years.

The surface engineering resin material uses infra-red reflection technology, which can reflect over 30% of infra-red ray. Under the same condition, the thermal conductivity of FFGI STEEL is 0.601. (w/m.k) ,and the thermal conductivity of PPGI/PPGL is 6.598 (w/m.k). The average temperature in interior building can be 10°C lower than PPG! steel sheet.

The PVDF coating has the function of "self-cleaning', and the dust is not easy to stick to the surface. As long as it rains, the dust sticking to FFGI steel surface can be washed away, thereby maintaining the original clean appearance of the building and extending the membrane Life.

Catalogs

No catalogs are available for this product.

See all of FANGXING BUILDING MATERIALS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.