- Heating, Air Conditioning, Electricity

- Renewable energies

- Solar inverter

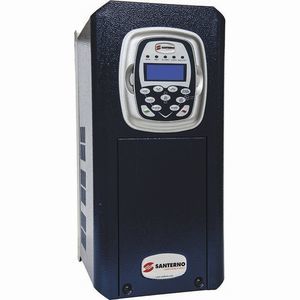

- Enertronica Santerno S.p.A.

Solar inverter SINUS Hthree-phase

Add to favorites

Compare this product

Characteristics

- Power source

- solar

- Phase

- three-phase

- Peak power

Min.: 400 W

(1 hp)Max.: 37,000 W

(50 hp)

Description

– Graphic LCD keypad featuring Multi-keypad function

– Smart Copier device enabling downloading/uploading the operating parameters and the firmware when the inverter is off

– Conduit Kit for cable routing, NEMA1 protection

– Flange Kit for the separation of the air flow for power section cooling.

– Communicator Kit for the conversion of the comms protocol: Modbus/Profibus DP, CANopen, Modbus TCP, Ethernet/IP

– Three-phase input/output inductors

– DC Input inductor

– Braking resistor

– Output ferrites

– Degree of protection IP66 available up to model 0030. Standard version featuring IP20

– Mains disconnect switch integrated into IP66 models

– Optional LCD graphic keypad

– Zero Stack installation

– DC input inductor: integrated into model Sinus H 0034 External DC inductor available for models Sinus H 0001…0030

– Braking module integrated up to model Sinus H 0030

– Overload up to 120% for 60s (Normal Duty)

– Overload up to 150% for 60s (Heavy Duty)

– Overload up to 200% for 4s

– Operating temperature with no derating: -10°C up to 50°C depending on the type of overload

– Integrated RS485 serial port, MODBUS RTU communications protocol

– Integrated EMC filter: type A1 or A2 depending on the model

– Integrated Safe Torque Off (STO) function. Certified according to EN61508, SIL2 and EN ISO 13849-1, PL d

– Standard compliance: RoHS, CE, EAC, RCM and UL

– Integrated control methods: V/F, Sensorless Vector Control and Sensorless Permanent Magnet Motor Control

– Integrated PLC function: up to 18 programmable logic blocks

– Energy Saving function

– Lifetime Detection (capacitors and fans)

– High torque even at low frequency values, 200%/0.5Hz

Catalogs

Other Enertronica Santerno S.p.A. products

Industrial Automation

Related Searches

- Management software

- Inverter

- Solar inverter

- PV inverter

- Three-phase inverter

- String inverter

- Monitoring software

- Online software

- Central inverter

- Inverter with transformer

- Cost estimation software

- Control software

- Automated software

- Data logger

- Residential installation inverter

- Photovoltaïc installation software

- Synchronization software

- Modular inverter

- Inverter station

- Residential inverter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.