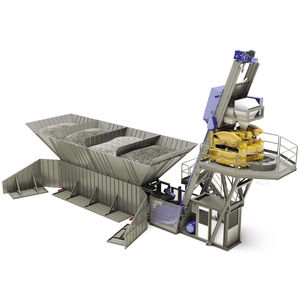

Concrete batching plant TOWER

Add to favorites

Compare this product

Description

Ideal solution for industrial concrete production

The EUROMECC Beton Tower is distinguished by its high production capacity and low costs of maintenance

- Diameter of tower silos - 8.500 mm

- Aggregate storage - from 360 m3 up to 620 m3

- Nr. of inside compartments - from 4 up to 12

- Hourly production - depending on the model and the number of mixers installed

- Loading of aggregate materials inside each compartment - by means of bucket elevator or conveyor

- Aggregate distributor - reversible belt with slewing ring

- Weighing systems for aggregate materials, concrete, water and additives - by means of homologated load cells

- Independent mixing points - one or more than one mixer

- Production - ready-mix concrete and precast concrete (the mixing platform can be equipped with no mixer (for dry productions), twin shaft mixer and/or planetary mixer.

- Automazion - customized depending on the customer's requests

- Reduction of spaces to be destined to the plant

- Sturdy structure and full use of the whole tower volume due to the circular shape

- Reduced production time, thanks to the absence of conveyor belts and skips

- Less energy consuption, thanks to a lower number of mechanical elements

- Euromecc tower plants are entirely hot dip galvanized, allowing several advantages such as: better protection of the surfaces, reduced maintenance requirement, longer life of the plant

- Internal designing and production: just one contact for all aspects concerning the plant

Catalogs

No catalogs are available for this product.

See all of CIFA S.p.A‘s catalogsRelated Searches

- Concrete pump

- Mobile concrete pump

- Truck-mounted concrete pump

- Stationary concrete pump

- Concrete batching plant

- Concrete mixer truck

- Mixer truck

- Trailer-mounted concrete pump

- Concrete mixer

- Diesel mixer truck

- Spraying machine

- Hydraulic mixer truck

- Concrete spraying machine

- Automatic concrete mixing plant

- Mobile concrete batching plant

- Concrete truck-mixer concrete pump

- Diesel truck-mixer concrete pump

- Truck-mixer concrete pump

- Fixed concrete mixer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.