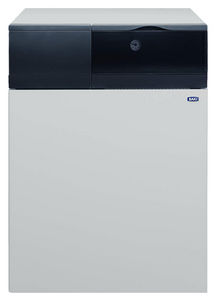

Solar hot water cylinder UBHY DCfloorverticalresidential

Add to favorites

Compare this product

Characteristics

- Power source

- solar

- Installation

- floor

- Orientation

- vertical

- Sector

- residential

- Capacity

270 l, 450 l

(71 gal, 119 gal)

Description

Features

Each model has a tank with doble coil, of which one specific for heat pumps with enhanced exchange surface, and a system side 80 litres puffer which function as hydraulic separator for both heated and cooled water

Flexible installation

Easy and clean installation

Magnesium anode to ensure internal surface protection against corrosion

Enamelled vitrified steel tanks to ensure high protection against corrosion

Insulation made with 70 mm rigid injected polyurethane

INSTALLATION INSTRUCTIONS

What follows is determinant for the warranty validity.

1. The installation must:

• Be executed by a qualified installer.

• Be provided, where necessary, with a pressure water reducing in entrance.

• Be provided with a safety valve according to the technical datas of the boiler.

• Be provided with an expansion vessel (see the measuring board of the expansion vessel) proportioned to the boiler’s

dimensions (it’s advised to size the expansion vessel by a thermal technician).

2. Before starting, you are invited to check the tightening of the hydraulic plug, apply torque 20 Nm.

3. The temperature of the boiler inside must always be under 95°C (70°C for the SMALVER models).

4. Each year an internal cleaning must be done.

5. In order to avoid corrosion, the anodes must be inspected after each 12 months. However, where the water is particularly

aggressive, the inspections must be done each 6 months; if the anode section is less than 22 mm, it must be replaced, if covered

with limestone is to be cleaned.

6. The water Langelier Index at the operating temperature, must range from "0" to "+0,4", hardness within 10°F and 25°F

Catalogs

No catalogs are available for this product.

See all of BAXI‘s catalogsRelated Searches

- Boiler

- Indoor boiler

- Home boiler

- Hot water cylinder

- Gas boiler

- Vertical hot water cylinder

- Electric hot water cylinder

- Condensing boiler

- Wall-mounted boiler

- Heating only boiler

- Fan coil

- Free-standing water heater

- Wall-mounted hot water cylinder

- Commercial boiler

- Wall-mounted fan coil

- Buffer tank

- Solar hot water cylinder

- Ceiling-mounted fan coil

- Water heater with heat exchanger

- Commercial hot water cylinder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.