- Products

- Catalogs

- News & Trends

- Exhibitions

Carbon reinforcing fiber CARBONCAST®

Add to favorites

Compare this product

Characteristics

- Composition

- carbon

Description

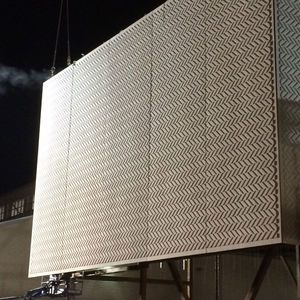

CarbonCast® Enclosure Systems use advanced technology to improve precast concrete by integrating ultra-strong, noncorrosive C-GRID® into the wall panels during fabrication. By taking the place of steel reinforcement, C-GRID® provides a multitude of benefits that makes factory-made precast concrete an even more intelligent choice for commercial building envelopes.

Depending on design, CarbonCast® panels are priced competitively with other curtainwall systems such as brick-veneer, masonry, stud walls or concrete. And after factoring in reductions to superstructure requirements and potential HVAC system and operating savings, CarbonCast® Enclosure Systems can provide a great ROI. Another benefit of this product for any owner is that CarbonCast® can achieve the aggressive building R-values needed to meet LEED requirements.

Lightweight, non-corrosive C-GRID® is the “enabling technology” that allows CarbonCast® Enclosure Systems to be lighter, insulating, more durable and cost competitive. C-GRID® has many of the same strength-weight benefits as high-performance aerospace carbon fiber, but at a significantly lower cost. The carbon fibers used to make C-GRID® are over four times stronger in tensile strength than steel by weight. Each carbon fiber “tow” or strand is comprised of thousands of ultra-fine fibers that are bundled together. These tows are assembled perpendicular to each other into a grid using a continuous rotary-forming process that chemically binds them with a tough, heat-cured epoxy resin.

Features & Benefits

Full composite action for load-bearing performance

Continuous insulation to meet aggressive R-value requirements

Aesthetic versatility

Fire rated

Related Searches

- Coating

- Woven wire fabric

- Building coating

- Building woven wire fabric

- Metal sheet

- Steel metal sheet

- Concrete block

- Protective coating

- Building concrete block

- Aluminum metal sheet

- Wall concrete block

- Stainless steel metal sheet

- Solid concrete block

- Retaining wall

- High-performance concrete block

- Concrete retaining wall

- Modular retaining wall

- Polymer coating

- Noise barrier

- Metal coating

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.