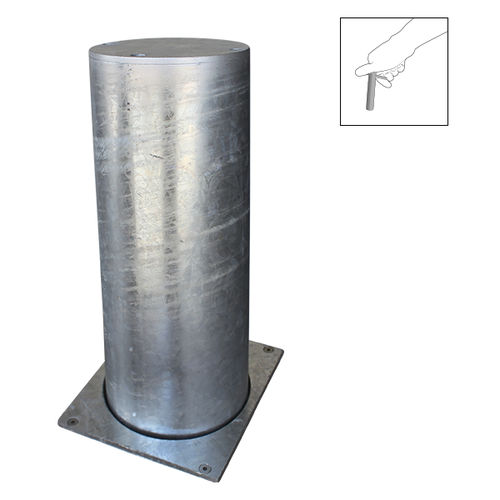

Upper-middle range hydraulic, London semiautomatic telescopic bollards, ideal for places which require impact high-resistance.

Semiautomatic bollards built with a tubular structure (rod), in galvanized iron. The chassis is made of high-robustness electro welded steel, hydraulic motor, galvanized iron box caisson with framing.

FEATURES:

- High quality gas piston drive system that allows the bollard to emerge after unlocking the anchoring mechanism.

- Opening and closing: it has a hole through which the lock can be accessed, thus unlocking the opening and closing mechanism. Lock bar constructed of stainless steel. Thus avoiding any type of wear and corrosion thus guaranteeing a long durability and perfect operation.

- When the upper part of the bollard is pressed, it descends, locking itself automatically once its journey is completed.

- By inserting and turning the supplied triangular key. The anchoring system is unlocked allowing the bollard to emerge again on its own and locking itself again in the high position.

- Bollard sliding system using interior guides located on the chassis itself.

- Cover built from 8 mm thick plastic-coated iron with no overhang on the level of the roadway, engraved in anti-slip rings form and inner plastic ring for the correct sliding of the bollard, avoiding noises and chafing.

- Chassis built of electrowelded high strength steel that has sliding rails to ensure the perfect alignment and concentricity of the bollard.

- Small installation depth.

- Installation of a lost casing. It allows the replacement of the bollard, once installed, without the need for civil works.

- Minimum preventive maintenance.