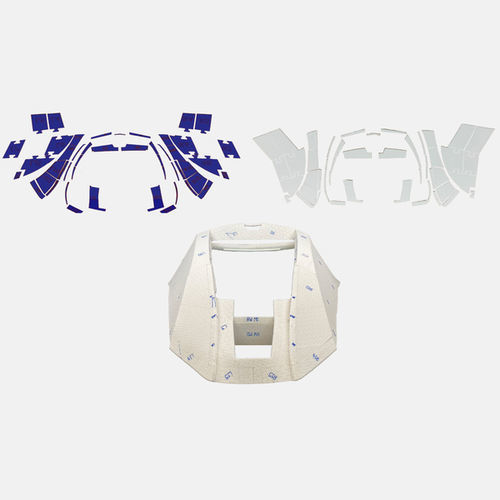

With our optimized and customized rapid assembly kits, you can make your production efficient, economical and sustainable. Your fix-in-place™ ASSEMBLY KIT is created from your 2D or 3D drawing. By nesting, the individual cuts from the cutting data are arranged in order to guarantee optimal material consumption. In addition, our engineering team will create a suitable insertion plan with the labeled cuts for your mould. These are precisely cut according to the final drawings, including all angles and curves. To ensure the fastest possible component production, the rapid assembly kits consist of both cut-to-size 3D|CORE™ foam core as well as scrim and fabric cuts. We are also happy to optimize your existing kit.

YOUR BENEFITS:

Sustainability:

- Optimum use of materials

- Reduced waste

- Energy savings during production

- Improved CO2 balance

One-stop solution:

- Cuts from foam core and fibres

- High time savings from the idea to the finished component

- Partnership instead of supplier relationship

Maximum flexibility:

- Fewer cuts

- No intermediate vacuum

- No gluing in

- Optimized radii and chamfers

Savings in:

- Storage costs

- labour costs

- Consumables

- Freight costs

- Energy costs

Patented fix-in-place™ technology:

- Easy insertion

- Labelled cuts

- Insertion plan

- High time saving

- Dimensional accuracy

- No full laminate between the individual cuts